Classroom teaching and homework. Course material: books and a course binder will be provided.

A basic knowledge of semiconductor physics and devices and of IC processing is needed for quite a number of functions: from IC technology engineers to test and product engineers and IC designers.

This course is an introduction course and lays the foundation and focuses on the relation between the semiconductor technology and the behavior of the devices.

This training is available for open enrollment as well as for in-company sessions. For in-company sessions, the training can be adapted to your situation and special needs.

Objective

After the course, the participant will have acquired:

- A basic knowledge of semiconductor physics and devices;

- A basic knowledge of process steps in IC technology;

- A basic knowledge of MOS IC processing;

- Some knowledge of bipolar IC processing;

- A basic knowledge of electrical process characterisation and monitoring;

- A basic insight in the relation between the semiconductor technology and the behavior of the devices.

Target audience

This course is intended for junior IC designers, test and product engineers, IC technology engineers, employees who need to have basic knowledge of IC techniques. Also for experienced engineers who want to extend their scope. Required educational level: BSc / MSc in Electronics, Physics or Chemistry. Experience and/or additional knowledge is not required but elementary knowledge on semiconductor physics and devices is very helpful.

Program

Introduction to and history of IC technology, simple process flow (1 x 3 hrs)

Semiconductor devices and device physics (5 x 3 hrs)

- Distribution and transport of charge carriers in semiconductors;

- Semiconductor fundamentals;

- PN junction diode;

- MOSFET transistors;

- Bipolar transistors;

- Small and large signal behavior, first and second order effects;

- Relation between the semiconductor technology and the behavior of the devices.

MOS and bipolar IC processing (5 x 3 hrs)

- Oxidation;

- Diffusion;

- Ion implantation;

- Chemical vapor deposition (CVD);

- Physical vapor deposition (PVD);

- Wet processing;

- Plasma etching;

- Photo lithography.

Several advanced topics (like high-K, SOI, FinFET) will be addressed briefly in the device physics / technology part: What are the essentials, the (dis) advantages and consequences.

Q&A, finished homework, exercises (1 x 3 hrs.)

Electrical process characterization and monitoring (2 x 3 hrs):

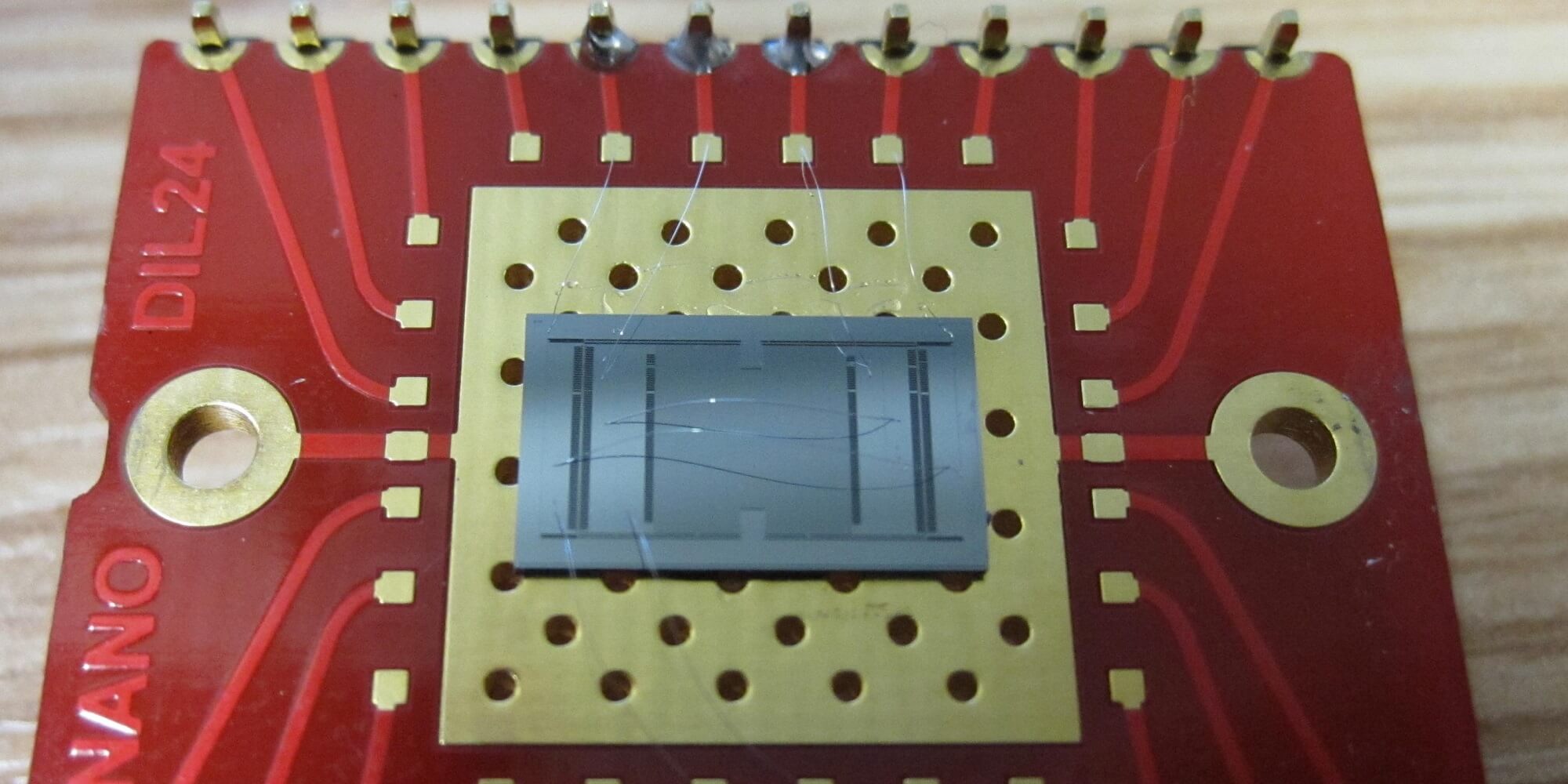

- Probe pads, PCMs (Process Control Monitor), PEMs (Process Evaluation Monitor);

- Measurement systems & SMUs (Source-Measure-Unit);

- Resistance measurements;

- Single layer sheet resistance evaluation and characterization;

- Test structures for inter- and intra-layer isolation;

- Contact resistance characterization.

Concluding session (1 x 3 hrs):

- Current developments on device physics, semiconductor devices and process technology;

- Homework, certificates and evaluation.

Methods

Certification

Participants will receive a High Tech Institute course certificate in case homework results are sufficient.

Remarks from participants