High Tech Institute’s teachers of the year

Trainers Kees Verbaan and Hans Vermeulen on the fun of training. They look back on the passive damping training at ASML in Wilton, for which they received the highest trainer score in 2022.

Kees Verbaan and Hans Vermeulen, the two High Tech Institute Teachers of the Year 2022, were surprised with their award. But not so much about the high appreciation behind it coming from the participants of the Passive damping training at ASML Wilton in the US. ‘Our story resonated there,’ both say. Vermeulen: ‘ASML is clearly leading in terms of technology development. You see that it has really become necessary to apply passive damping. There are multiple dampers in a lithographic scanner, actually in these machines you find them all over the place.’

Technology professionals at ASML are relatively well trained and have often been involved in many complex problems. Vermeulen: ‘Teaching such a group of engineers on site implies a lot of interaction. They keep up very well in terms of knowledge level. The subject also suits them. Unsurprisingly they came with a lot of critical questions.’ Verbaan: ‘You feel the urgency. It was great fun to have discussions with them on the cutting edge. Many of the engineers also had a dynamic background, so actually all the topics of the course resonated well.’

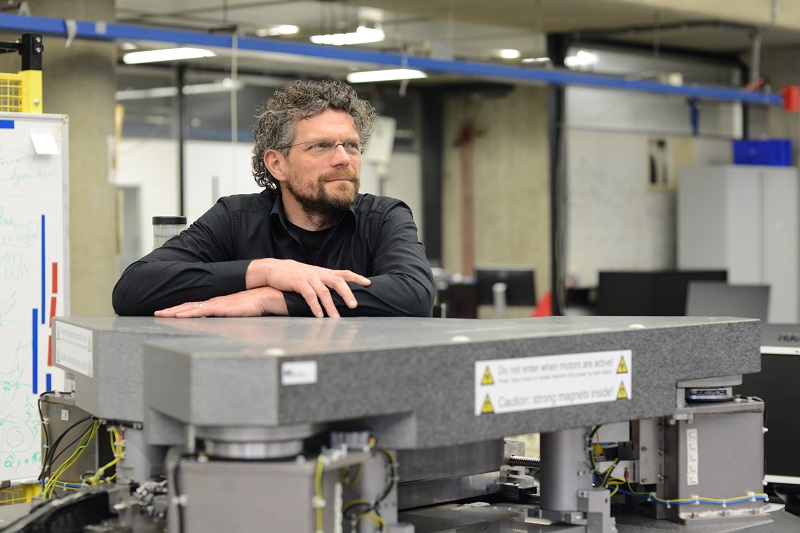

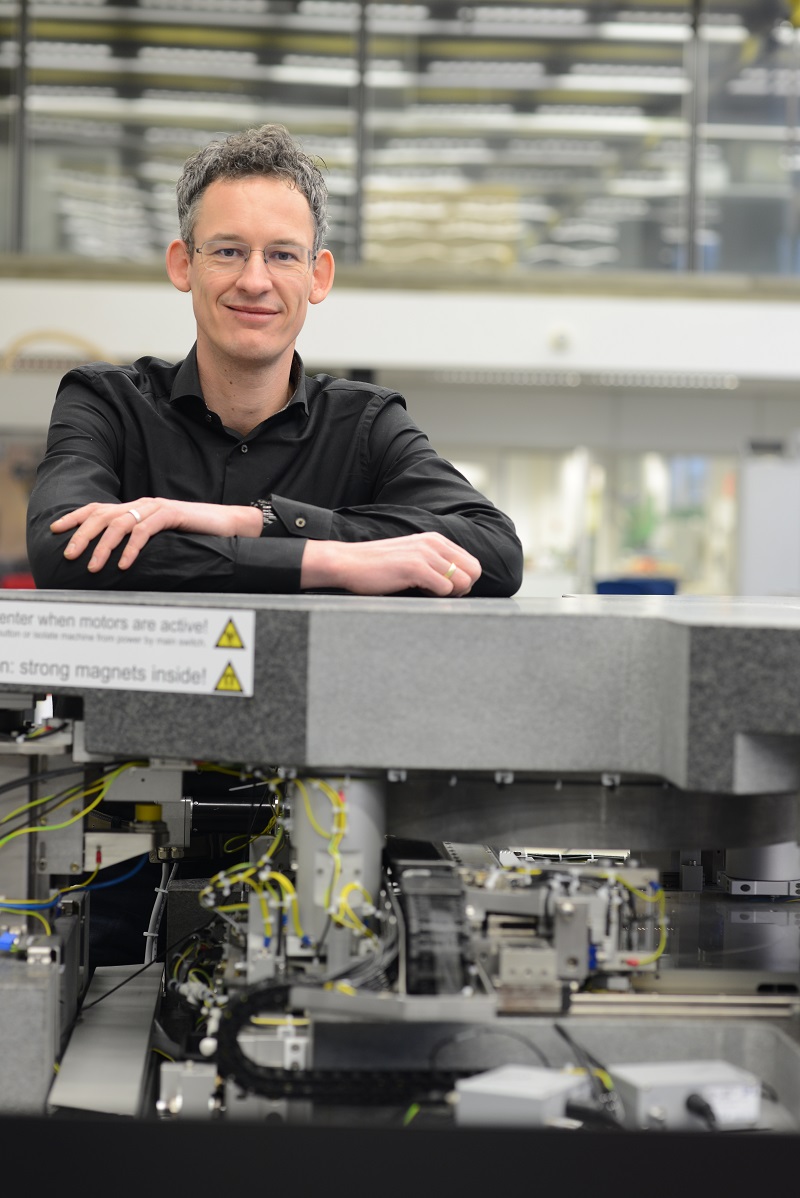

Prof. Hans Vermeulen at Eindhoven University of Technology.

The need for trainings at ASML is driven by the large influx. ‘At all development sites they bring in a lot of people, also in Wilton,’ says Vermeulen. ‘When I was there for ASML Research in 2017, they had about 350 development engineers on the payroll. I think that number has quadrupled by now.’

The main purpose of the trainings is to get everyone in the organization speaking the same language. ‘Starting mechatronics engineers follow the same curriculum of four basic training courses. The basic ‘Mechatronics’ training part 1 and 2, ‘Dynamics and modeling’ and ‘Passive damping for high tech systems’.’

''The goal is to extract energy from a system to reduce unwanted vibrations.''

Passive damping is the most recent one. The field of knowledge is on the rise because traditional design methods based on masses and springs alone are no longer adequate enough for the latest demands. In the past, it was not necessary. For a long time, technical designers found head room to increase resonance frequencies through lighter and stiffer structures to achieve required precision. But we are running more and more towards limits. ‘Therefore, we started to reduce vibration amplitudes at resonances by means of damping,’ Vermeulen says. ‘It is an element you have to build in carefully. The goal is to extract energy from a system to reduce unwanted vibrations. But it can come at the cost of your positioning accuracy if you don’t apply it properly.’

Should every mechanical engineer in a high-tech company know about it?

‘In any case, it’s good to be aware of it. In civil engineering, damping has been applied in skyscrapers and bridges for decades already.’ Vermeulen finds it difficult to draw a comparison with his own field, but he still sees things going wrong these days. ‘There are sometimes resonances in airplane wings and bridge decks that could have been avoided if the relevant analyses would have been done, as for example for the London Millennium Bridge. Whatever field you come from, as an engineer it’s good to know how to apply it. But it starts with sound mechanical design. The moment you need it, it’s handy to have it readily available.’

Verbaan: ‘Not everyone needs to be able to implement it in full detail, or be able to fully calculate it. But a good understanding of how to create lightweight and stiff structures, after which you might apply damping to get to an optimal result, is something I think you need to have.’

Dr. Kees Verbaan at Eindhoven University of Technology.

Verbaan says about the fun of the training: ‘It’s great fun when you understand a subject yourself and then witness that someone is really getting the message. That generates a lot of enthusiasm in that person, but also for myself.’

Vermeulen says he recognizes this. ‘I very much like to get things really across. The training is also designed with that goal in mind. We discuss how to deal with damping mathematically, about mass, spring and damping matrices. But in addition, very early in the course, participants practice with an elementary case on how to reduce the vibration amplitude of a mass-spring system say by a factor of one hundred in ten cycles through dissipation of energy. Then it sinks in what it means to apply damping.’

''We awaken the interest they need to tackle in other cases later on.''

Verbaan: ‘They start thinking: ‘What does that mean’?, and then rapidly see what a damper really does and what definitions mean that go with it. In this way, we awaken the interest they need to tackle in other cases later on.’

Besides the elementary basics, the two also cover design and modeling, and a practical exercise to implement it themselves. In addition, also how participants can apply it in their own practice. ‘That combination creates a very nice interaction,’ Verbaan says. ‘Some engineers are very much into modeling, others have more practical experience. We see a lot of interaction between participants there, and we get a lot of energy from that.’

What is the interaction like in the passive damping trainings with open enrollment?

‘There we see more mixed and diverse groups,’ Verbaan says. ‘There it is sometimes more challenging to get everyone to join in immediately on every single topic. For materials scientists, the experience is much different from someone who is used to work with complex dynamic models. In Wilton, all the topics resonated well with all the people.

This article is written by René Raaijmakers, tech editor of High-Tech Systems.

Recommendation by former participants

By the end of the training participants are asked to fill out an evaluation form. To the question: 'Would you recommend this training to others?' they responded with a 9.2 out of 10.